Welcome to Marcellus-Shale.us

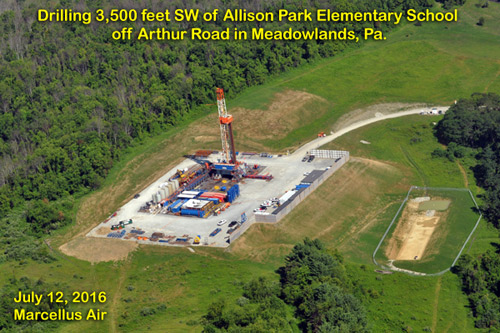

The best visual Marcellus Shale gas drilling information source with aerial photos

91 123-456-7890

New pipelines for Marcellus Shale gas

In 2016, half the pipelines in Pennsylvania were at least 45 years old with the majority of US pipelines installed before 1970. Corrosion accounted for 28% of serious pipeline accidents.

Our Work

Photos of Marcellus Shale & Utica Shale gas extraction

What Our Clients Say

This Marcellus Shale gas drilling web site provides photos and information about the Marcellus Shale gas play and unconventional gas well development. You’ll find photos of gas drilling sites, pipeline construction, unconventional wells and compressor stations.

Export of gas liquids from Marcellus wet gas

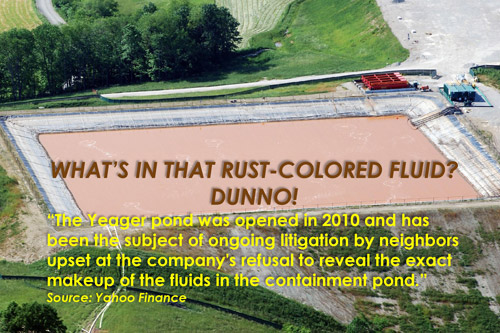

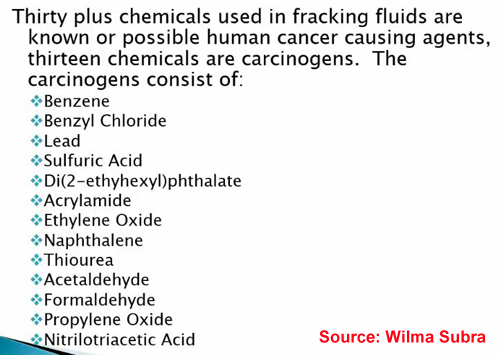

Citizens have the right to enjoyment of their property, as well as a healthy environment including clean air and pure water as guaranteed by the Pennsylvania Constitution.

Our Expert Team

Citizens have the right to enjoyment of their property, as well as a healthy environment including clean air and pure water as guaranteed by the Pennsylvania Constitution.

6,820

Clients

4,000

Projects

3,568

Repairing

1,530

Awards

News & Events

The Impact of Institutional Investors on the Cryptocurrency Market

Introduction The cryptocurrency market has experienced a remarkable evolution, marked by the increasing involvement of…

xBitcoin Club: Decentralization vs. Centralization: The Role of Bitcoin in Ensuring Financial Freedom

Introduction Welcome to the xBitcoin Club, your go-to destination for all things Bitcoin and decentralization….

Unearthing Opportunities: Investing in the Mining Industry for Sustainable Growth

Introduction The mining industry has long been a cornerstone of global economic development, providing essential…